West Bend, WI – Over the last 15 years, Dave Bohn has been writing down memories of his childhood, growing up on the family farm just south of West Bend on Hwy P.

He hopes his writings will preserve the often overlooked stories of ordinary farmers and everyday farm life in rural Washington County during the Great Depression through the eyes of a local farm boy.

Steam Tractor with Water Tank. Circa 1920. My dad is on the far right. Olive Werner, Clara Bohn, ?, Lorraine Werner, ?, Arnold Bohn, Dan Ollinger (bib overalls), ?, John Bohn

When I was growing up in the 1930’s, it was a transition time for farms. Most farms were 80 to 100 acres, as this was all a farmer could till with his horses. Tractors were just starting to come in and horses for farm work were going out.

In my youth, the only people I remember who had a tractor were the threshers. In my dad’s day, threshers were run by a steam engine tractors. But in my early days, Oil Pull tractors were used. These tractors would pull the threshing machine from one farm to the other but their main purpose was to supply the belt power to run the thresher by running a continuous belt off a pulley.

This Oil Pull tractor did not look like tractors do today, as it was a big tractor, about 7-feet high and would only travel about 2 miles per hour while moving on the road. At this time, tractors were not used to work the land.

The Oil Pulls were big and clunky but to run machines, they did work. When the Oil Pull and threshing machine would pass our place, we always liked to watch this big moving operation, as did other farm families.

After threshing, they would move the threshing machine with the Oil Pull to the next farm. When I was a kid, threshing time was the biggest time of the year for the farmers. The threshing would separate the grain from the stalks.

On our farm, we planted oats, wheat, and barley; those were the grains we grew. In the spring, when the ground had thawed from the winter frost, in late April or early May, we planted the grain. Dad would plow the fields each fall to turn the soil over and then in spring, he would loosen the soil by hooking up a spring tooth harrow behind two work horses. After the soil was loosened, he would plant the seeds. My brother, Tom, who is two years older than me, remembers being on Jim, the big draft horse, from morning to night, helping Dad with the planting.

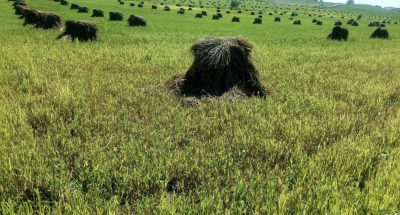

In about 90 days, the grain would form the seed head and be ready to harvest. Usually, this occurred in mid July. When the grain was ready to harvest, it was cut and tied in round bundles by a binder pulled by two horses. The bundles were collected and about four were put on a carriage on the side of the binder. As the binder moved forward to cut the next row, the carriage would drop these bundles on a pile in the field. Dad would place the bundles in the same general area in each row so they were all in the same place, making it easier to shock the grain. When the field was all cut, the bundles had all been dropped in a row.

The next step was the shocking, which is setting the bundles upright with the grain heads up and the cut edge on the ground. Six bundles were set next to each other to keep them all upright. The bundles would have to be set on an angle so air would flow through the center and the grain would dry.

Then we would place one bundle on top of the six bundles to act as a sort of rain shed and prevent water from getting to the seed heads. That method usually kept the seeds dry. In four or five days (sometimes sooner, depending on the weather), the grain was dry enough to thresh. It must be dry when threshed or it will spoil in the grain bin if there was any moisture in the kernels.

On threshing day, about six neighboring farmers would help each other. The threshing machine moved from farm to farm to thresh each farmer’s grain and it would be on one farm till that farmer’s grain was all threshed.

On our farm, it was usually just one full day. It would take about 10-14 days to complete all the farms in our area. Only one farmer had the threshing machine and they would all use this same machine because of its expense.

My dad used the threshing machine of Mike and Frank Spaeth for the early years that I remember of threshing. They were the farmers that owned the Oil Pull tractor. Later, he used the threshing machine of Ambrose and Pius Wiedemeyer and in other years, he used Harvey Bohn’s. By that time, those farmers had more efficient tractors to run the thresher.

Click HERE for more stories of farming and growing up in West Bend by Dave Bohn

The owner of the threshing machine would charge each farmer by the bushel for use of the machine. There was some sort of scale on the threshing machine to count the bushels of grain, so the farmer running the thresher would know what to charge.

Threshing day wouldn’t start until the dew had dried off the shocked grain stalks. Three or four farmers would bring their horse drawn wagons at around 9 a.m. to the farm that was to thresh that day. While the dew was drying off the grain, the threshing machine was pushed into the upper story of the barn with the blower pipe extended outside over the back cow yard. The blower pipe was for discharging the grain stalks and the chaff after the grain had been separated. The Oil Pull tractor was parked outside the barn so the fumes didn’t get into the barn and cause a fire.

The farmers with the wagons would go into the fields where the shocks of grain stood. Two additional men would be out in the field to help load the wagons. When we were old enough, my brother Tom and I would be the loaders, along with the farmers who drove their wagons. This job is what took the most manpower on threshing day.

The farmer with the wagon would stay on the ground with us until his wagon was fully loaded. The horses knew what was expected of them, so the farmer would make a clicking noise with his tongue and the horses would know to move ahead to the next shock of grain. We would stay in the field and help the neighboring farmers load their wagons with the grain. This could take all day, as an empty wagon always returned to the fields for another load.

When each load came back to the barn, the horses would pull the wagons full of grain next to the threshing machine. Two men standing on the wagon would throw each bundle of grain onto a wide moving belt that would take each bundle, one at a time, and drop it into the threshing machine. The bundle would go into the threshing machine with the stalk heads first.

There were rotating knives that cut the strings around each bundle. Then the bundle moved to the actual threshing portion of the machine where the grain was separated from the stalks and the chaff. The by–product of the grain was blown by a big fan out the blower pipe onto a stack in the back cow yard below.

The blower pipe had two hand-operated cranks. One crank was used to move the pipe up and down and one crank was used to move the pipe sideways to form the shape of the straw stack. One man or boy would be in charge of the blower. There was another man who was on the straw stack down below in the back cow yard to make sure the stack was neat and orderly.

It was a dusty job, as this was done as the stalks and chaff were being blown out onto the stack. On our farm, one of our bachelor neighbors, Louis Schloemer, took care of this job. It was the dream of every farmer though to have a neat straw stack and Louis did a good job.

Once the grain was separated, it went to a short pipe to a place where it went into bags, one bushel at a time. This pipe had a drop bottom bucket, about the size of a bushel, that was attached to the end of the pipe on the thresher. Once the bucket was at the correct weight for a bushel, it would trip to open the bottom of the bucket and the grain would pour out into the bag below. The bushel count was the count the owner of the threshing machines used to charge the farmers for use of the thresher. Most farmers liked a big bushel count, as it showed how productive their farm was.

Once the grain was in the bag, one farmer would grab the top of the open bag and cinch it shut with his hand, while another man grabbed the bottom and helped heft the open bag up to the farmer’s shoulder. The farmer carrying the bag of grain would then carry it into the granary, which was a room on the upper level of the barn.

Once in the granary, the grain was poured into bins. There was a separate bin for each different grain that was threshed. Each bin of grain was about 10 feet x 10 feet and about the shoulder height of a man. When the bin started to fill on the one side, a kid would have to get into the bin and shovel the grain back away from the side to make room for additional grain. Sometimes this became the job of me, Tom, and our younger brother, Jerry.

Threshing time was always a festive time, as there was always plenty of beer to be had. Some of the men would overdue this part and have a little too much. Midway through the morning, about 10 a.m. – 10:30 a.m., a lunch was served. It was just a sandwich and a beer most of the time. The whole operation would shut down and all the farmers helping with the threshing would come back into the barn for this break and to visit.

The ladies of the house where the threshing was being done were to serve a big noon meal for the entire crew. They always wanted to show how good of a cook they were and they would put forth their best cooking abilities for this meal.

My mom would prepare the meal with the help of my Aunt Ida Spaeth, who lived just down the road on the farm where the Washington County Fairground is now. My mom always served this meal in our house. The men would eat in both the kitchen and the dining room.

When we were old enough to be one of the crew, this meal was the best part of the day, as the meal was always top notch. For the noon meal at our house, it was usually roast beef with mashed potatoes and gravy and all the trimmings. As a kid who liked to eat, this was like heaven as we very seldom had roast beef on the menu. We always had pork or chicken, as this was what we raised on the farm.

Threshing time is now history, along with straw stacks and the excitement of threshing days, as combines have made a simple thing of grain harvesting. During the WWII years is when farming really changed. They had to invent more efficient machines that would allow farmers to produce more per acre with less manpower because so many young men were being drafted into the service. So, the Oil Pull tractors and threshers eventually went the way of steam engine tractors and farming changed altogether.

Threshing time is now history, along with straw stacks and the excitement of threshing days, as combines have made a simple thing of grain harvesting. During the WWII years is when farming really changed. They had to invent more efficient machines that would allow farmers to produce more per acre with less manpower because so many young men were being drafted into the service. So, the Oil Pull tractors and threshers eventually went the way of steam engine tractors and farming changed altogether.

But when I was a kid, threshing time was probably the most exciting time of the year. So much action on all the farms at the same time. Neighbor helping neighbor. Most farm tasks have changed the way farming is done now from when I was growing up on our farm in the 1930’s and 1940’s. But the days of threshing will always remain with me as a wonderful memory of my life in the past.