West Bend, WI – Over the last 15 years, Dave Bohn has been writing down memories of his childhood, growing up on the family farm, just south of West Bend on Hwy P. He hopes his writings will preserve the often-overlooked stories of ordinary farmers and everyday farm life in rural Washington County during the Great Depression through the eyes of a local farm boy.

My parents didn’t have a refrigerator until WWII ended. They didn’t have an ice box either. So, when I was a young boy growing up in the Depression, they had to preserve meat by different means.

Click HERE to SUBSCRIBE to FREE local news at

Washington County Insider on YouTube

All farms had a designated day in the wintertime to butcher a hog for their family’s meat. That day almost always was after Christmas when the weather was sure to be cold. Farmers used the weather to keep the meat cold, as there was no means of refrigeration at that time, other than the weather.

My dad’s cousin, Ray Spaeth, was the main butcher for our family. Ray’s mom, Aunt Ida Spaeth would join my parents on that day and help with making pork sausage, Schwartenmagen, and preparing the hams and the pork chops. Another cousin, Isadore Spaeth, would help pretty often, too. Once in a while, other people would show up on butchering day, but it was mainly Aunt Ida, Ray, Isadore, Mom and Dad, and Grandma and Grandpa Bohn. They would come to our farm on our butchering day, and our family would go to their farm on their day.

When I was about five years old, Dad took me along when butchering day was at my Uncle Albert and Aunt Ida Spaeth’s farm (located on the Washington County Fair Grounds). My brother Tom and sister Mary Ann were in school, and my little brother Jerry was a toddler, so Dad just took me.

Uncle Albert and Aunt Ida had built a new house and they used the kitchen of the old house to process the meat. They had the ground up meat from the hog in a washtub standing on the floor, waiting to be made into sausage links.

I was a little chubby back then and wasn’t too steady on my feet. Somehow, I backed up and fell backward into the tub in a sitting position. Being a chubby kid, I was stuck and couldn’t get out of this tub full of ground meat. Some of the working men had to pull me out. It was pretty embarrassing, even for a kid.

It must have been quite a sight, a chubby little boy sitting in a tub of ground meat, struggling to get out! My brother Tom still laughed about it last year and said that I never lived that one down.

On butchering day, Dad and Ray and others would butcher two or three hogs at a time, so it was quite a job that took the whole day. After butchering, they would grind up some of the meat to be used for sausage. They kept the chops separate, as well as the hams and bacon for smoking.

The hams were soaked in saltwater and then smoked to preserve the ham. We had a small wooden building on our farm, about 8 feet x 4 feet, that we used to store coal most of the time. It also served as our smokehouse for the hams and bacon at butchering time. The bacon was cut from the whole side of the hog and was about 20 inches, depending on the size of the hog.

The hams and the sides were strung up from the rafters of the smokehouse at eye height. To smoke the hams and the bacon, Dad would spread sawdust on the dirt floor from hardwood trees like hickory or oak, but mostly hickory as it gave off a good smelling smoke. Dad used sawdust that was a byproduct from making lumber on the farm. The sawdust didn’t burn; it smoldered, creating the smoke. Dad would get the sawdust smoldering right on the dirt floor of the smokehouse and the hams would smoke for about three days. He would monitor the smoldering and add more sawdust when the smoke subsided.

After the hams and sides were smoked, the coal was put back into the smokehouse for storage. The coal was on the floor in a pile about 10 inches high. The hams and sides would hang there with the coal until we needed them for a meal. The hams and sides would last a long time out there in the smokehouse, almost all summer.

When Mom wanted bacon, Dad would go out to the smokehouse and cut a hunk off the side and bring it into the house where it was cut into thin strips. Because it was smoked, Mom could keep the meat in the house until we used it up. This was one way bacon was preserved.

To make the sausage on butchering day, the women would clean out the pig intestines to be used for the casings. Aunt Ida and Mom would take the casings into the kitchen and clean them before the ground meat was stuffed into them. There was always at least two women who would clean the casings, as they socialized during their work.

Aunt Ida was always one of them. She was real nice and a hard worker, so she didn’t mind the work and she liked the camaraderie of it. We didn’t have running water yet, so I suppose they boiled water to clean the intestines they used for casings. The local butcher shop always had casings for sale that were already cleaned. If the women didn’t want to clean them or if they needed more casing for sausage, they would purchase the casings to make butchering day a little easier, as it was a lot of work to clean the casings.

While the casings were being cleaned, the others would add the sausage spices to the ground meat and mix it together. The meat was about the same consistency as brats are today. They would put the ground meat mixture in a small tub-like machine which we called a stuffer. It was a hand cranked 3-gallon drum machine.

There was a 1 ½” long tube at the bottom which was about an inch in diameter. The casing was attached to the tube by being stripped over the top of the tube. As the person turned the crank, the sausage meat would squeeze out into the casing at the bottom of this tube. About every six to seven inches, someone would twist the casing to cut off the meat supply and form one sausage link. The ends of the casing were twisted shut, too. After stuffing the sausage, they sometimes would half-cook the sausage, but most of the time, they didn’t.

We had a stove that was specifically made for butchering. The stove top was about 36” in diameter with one burner. There was a door underneath the burner that held the wood fire. This stove was kept in our garage shed. Dad would just move the car out of the shed when it was our day for butchering so they could use the stove.

Once the fat was removed from the hog, it was put in a really big kettle that took up the entire stove top. They would heat the fat to melt it and form lard. Then they laid the sausage links in large 10-gallon earthen crocks and poured the melted lard over the sausage. The lard would smother the sausage links all around and there was at least 1/2″ layer of lard at the top of the crock.

As the lard cooled, it solidified and formed an air seal to prevent spoilage. The lard preserved the sausage which would last through the summer. Mom would store these crocks of sausage in our cellar on the floor. The sausage links were layered in the crock, so Mom would just scrape off the lard on top and pull out what she needed. As there was a lot of lard in between the sausage, there would still be an air seal.

The bacon was sometimes preserved with lard in crocks, too. Sometime after butchering day, Mom would put quarter inch thick bacon strips into 10-gallon earthen crocks with lard. The bacon was stored with lard to prevent air from getting in and spoiling the meat. It would keep all through the next summer without refrigeration.

There weren’t many chops, but whatever we had were eaten up fairly quickly. If there were extra chops, they were put in large 5-gallon earthenware jars and covered with lard to preserve them but that rarely happened.

We would eat the tongue about a week after the butchering was complete. Mom prepared it with a kind of sweet-sour taste. She would either boil or fry the tongue and the heart, just like regular meat. As a kid, I didn’t mind the tongue or heart, but I wasn’t too crazy about them either. They had a different taste and texture.

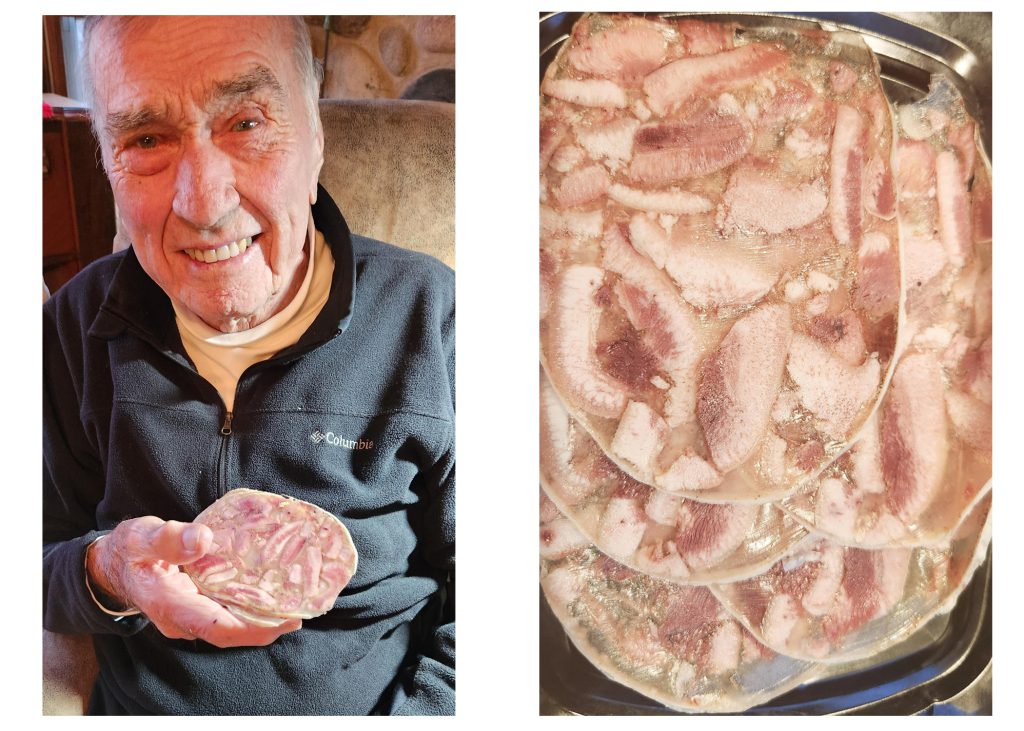

We also made Schwartenmagen on butchering day. Most people nowadays know it as head cheese. It was made with anything left over from the butchered hog. The pieces were held together with some kind of gelatin. Magen means stomach in German.

Back then, the stomach lining was used as the casing, so it had more of a loaf shape. Schwartenmagen wasn’t a common thing in our diet, but Mom and Dad made some of it. I really don’t remember eating it that often, so they probably didn’t make too much of it. The Schwartenmagen had a different taste too, but I kind of liked it. I hadn’t had Schwartenmagen for a long time, but I recently ate a piece that was purchased from a deli, and it tasted just as I remembered.

Mom would also make soap during butchering time. She would make the soap about two weeks after butchering day when she had all the ingredients. She most likely used the lard from the butchered pigs. She made the soap in the side porch at our house so there was ventilation. Mom always used Eagle brand lye when making soap.

When the soap hardened, Mom would cut it into individual bars. This lye soap that Mom made was only used for washing overalls and work clothes. She would shave off some soap from the bar to use for washing the clothes. The men would sometimes use it to clean their hands only if they had really ground in dirt as the lye was too harsh to use on skin in general. I think Mom bought separate soap for bathing and hair washing.

These winter days remind me of butchering days from long ago. It really isn’t done on too many farms anymore, but it is a day I always remember.